We have maintained wind power generators, mainly GE 1.5 series, and conducted 24H monitoring for more than 15 years. Currently we operate and maintain more than 10 types of wind turbines.We made original improvement by failure analysis and data analyses. Parts stock program and original supply chain are established through worldwide. For new large wind turbine, we can cooperate with Wind turbine suppliers.

Perform the scheduled and unscheduled maintenance

Maintenance of control panel

Maintenance of control panel Maintenance of control panel

Maintenance of control panel Inspection of generator brush

Inspection of generator brush Tighten of bolt

Tighten of bolt Tighten of bolt

Tighten of bolt Tighten of bolt

Tighten of bolt Maintenance of gearbox

Maintenance of gearbox Maintenance of gearbox

Maintenance of gearbox Nacelle

Nacelle Parts storage

Parts storage Parts storage

Parts storage Parts storage

Parts storage

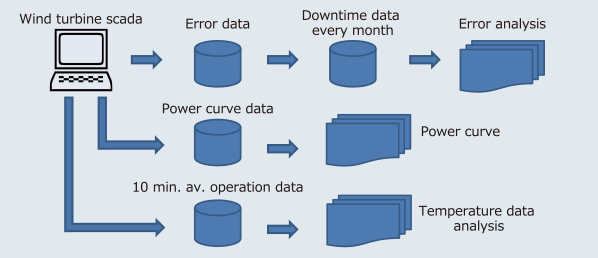

According to data analysis of SCADA, we perform preventive maintenance and improvement proposals by various results of error and state analysis, CMS, and Inspection (endoscopic, non-destructive examination: PT, MT, UT, vibration analysis etc.)

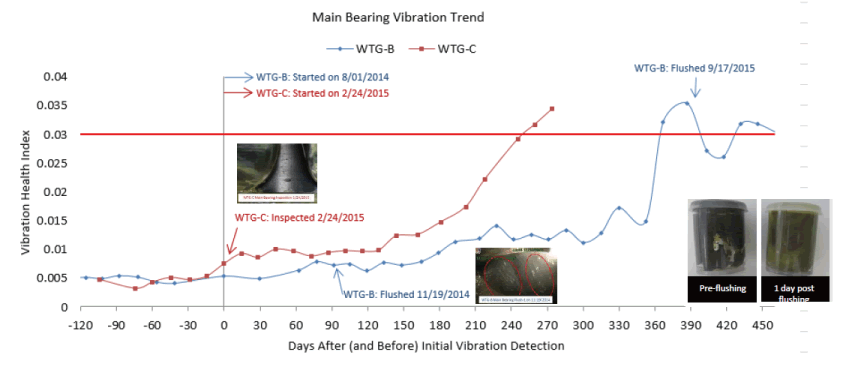

Regarding CMS, we introduced the eco-CMS (CONDITION MONITORING HARDWARE) manufactured by ONYX Insight. By analyzing the damages of wind generators and replacing dirty grease to new one due to our main bearing flushing device, we offer improvement solutions for reducing the internal damages and life prolonging of main bearings.

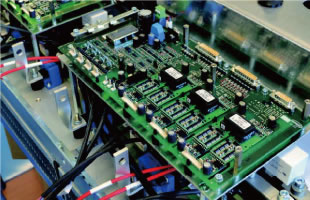

In addition, we suggest reduction in costs with substituting converter parts of wind power generator to manufactured by ZOPF.

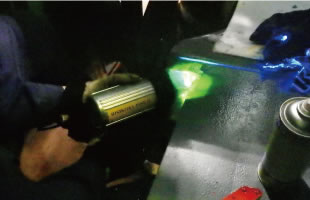

Frame MT inspection

Frame MT inspection Frame MT inspection

Frame MT inspection Bolt UT inspection

Bolt UT inspection Bolt UT inspection

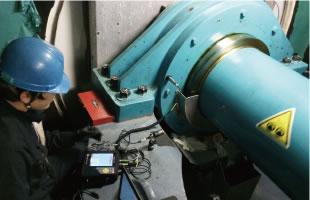

Bolt UT inspection Vibration measurement

Vibration measurement Endoscopic Examination

Endoscopic Examination eco-CMS

eco-CMS MB flashing

MB flashing MB flashing

MB flashing MB endoscopic examination

MB endoscopic examination IGBT board manufactured by ZOPF

IGBT board manufactured by ZOPF

Flow chart