Duties as a deemed installer, including as a chief engineer

24-hour monitoring, including output control systems

Remote Monitoring and Control

Remote monitoring and control of facility information, including information on wind power generation equipment, solar power generation equipment, and batteries

We provide remote monitoring and control of related facilities and equipment nationwide, 24 hours a day, 365 days a year.

Although there are various manufacturers and models, all equipment-related information (e.g., equipment failures and maintenance work notifications) is collected at our Data Management Center, and this then performs initial responses such as remote operation and updating equipment data.

If a response is required that is outside the scope of remote control, we work with the local office near the relevant facility to ensure it can be performed smoothly. In addition to these responses and controls, we monitor operational information such as daily reports, parameter management, output adjustments, and wind sectors, and carry out daily equipment maintenance, to enable early detection of abnormalities both before and after failures and prevent serious accidents.

Performing remote operation

Performing remote operation at the Data Management Center as an initial response to an equipment failure.

Data Collection and Analysis

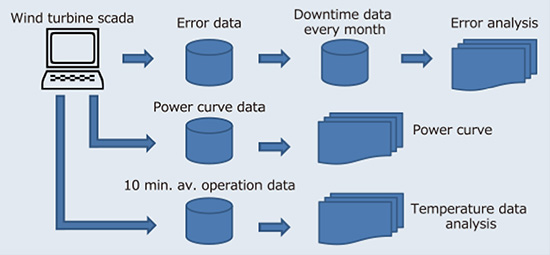

Collection, analysis, and management of data on equipment errors, numerical values, and conditions

By collecting and managing equipment data, we analyze errors, numerical values, and conditions, then conduct preventative maintenance and propose improvements.

Depending on the abnormal conditions detected from the data, we analyze whether they are attributable to mechanical factors such as vibrations and temperature, weather-related factors, or age-related deterioration, then appropriately identify the underlying issues.

We work every day to accumulate and manage this data so that it can lead to appropriate preventive maintenance.

Through sequences of tasks like these, we accumulate data and conduct various analyses.

Power Generation Forecasting

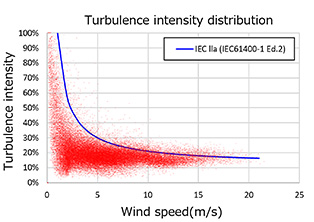

We perform wind power generation forecasting by examining meteorological data, equipment conditions, and operational data

By collecting and analyzing weather conditions (lightning, snow, rain clouds, etc.) and wind speed and direction, we aim to provide a stable power supply and efficient power sales operations.

We calculate appropriate power generation forecasts based on same-day, next-day, weekly, monthly, and annual weather forecasts, wind speed forecasts, and operational data.

Using the calculated power generation forecast results, we coordinate with the business sites that operate the facilities to decide inspection and maintenance outage plans, and work with them to ensure that operations will be based on appropriate power generation forecasts.

We manage output and adjust equipment to match fluctuations in power generation volume, and at the same time aim to maximize customers' revenues and ensure a stable supply.

Performing daily weather forecasting using various information

We collect wind speed and direction data, then use it to improve the accuracy of power generation forecasts.

Battery Management and Support for Post-FIT Wind Turbine Operations

Operational management based on battery management and various forecasts

We manage the remaining capacity of storage batteries by carefully examining various forecasts, such as weather conditions and wind speed.

Furthermore, by utilizing these forecasts and managing the turbines' output appropriately, we are also able to provide support for post-FIT wind turbine operations.

We manage battery charging and discharging in accordance with the actual amount of power generated under a power generation plan formulated based on power generation forecasts, and manage the remaining capacity appropriately.

Operational Planning and Wind Turbine Life Extension Operation Services Based on the Amount of Power Generated

Based on our extensive technology and experience, we assess the condition of our customers' wind turbines and propose operational solutions that balance safety and economic efficiency

Note: Availability is subject to the supported turbine models and the provision of operational data from the customer.

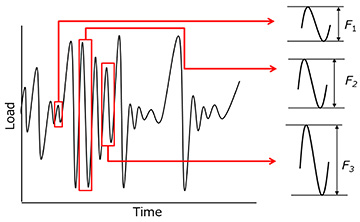

By carrying out aeroelastic analysis and component inspections, we can estimate the remaining life of our customers' wind turbines, and help them operate them efficiently.

We also evaluate additional CMS measurement data and SCADA data, then use the results to propose technologies for safe and economical mid- to long-term extension of operational life.

Examples: Proposing abnormality detection methods for components with a high risk of damage

Proposing operating methods that mitigate damage risk

If replacement of major equipment is required based on the results of these evaluations, we propose a replacement plan tailored to each individual wind turbine.

Business

- Operation and Operational Management of Wind Power Plants

- Maintenance and Inspection of Wind Turbines

- Supervision of Wind Turbine Construction

- Large-Scale Repair Work

- Blade Maintenance, Inspection, and Repair

- EES Training Center

- Sale and Maintenance of Safety Protective Equipment, Workwear, and Various Kinds of Maintenance Equipment